Tikka T3 / T3x - AICS conversion kit

- Brand: Lumley Arms

- Product Code: T3-DBM-AICS-CONVERT

- Availability: In Stock

-

$82.00

Our stock: in stock

Or buy from a distributor:

Tikka T3 / T3x

AICS conversion kit for rifles with the 'CTR' pattern bottom metal

For Tikka T3 / T3x owners without the factory CTR bottom metal, we offer a complete bottom metal inclusive of the trigger guard, action screws and pillars on this link here

This kit converts the CTR pattern bottom metal found on select Tikka T3 models and the Colt C-19 to accept any short-action AICS pattern magazine (223 / 308 / WSM). We supply a replacement magazine well and replacement lever that attaches to your existing trigger guard and reuses the same factory action screws (these last two components are not included in this kit). AICS

magazines have a number of advantages over the CTR magazines. These

include allowing a longer COAL, a lower price for comparable quality,

being available to suit more cartridge case types, and being made by

more manufacturers. As of July 2024, the compatible models for this kit are:

Features

- Machined from 7075-T76 aerospace alloy then hard coat type 3 anodized

- Accepts all short action AICS pattern magazines (223 / 308 / WSM )

- Ambidextrous fit to both right-handed and left-handed rifles

- Includes magazine lever dowel pin and lever coil spring

Construction

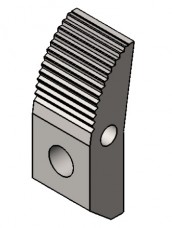

- The magazine well is CNC machined from high quality 7075-T76 aerospace alloy then hard coat anodized (black)

- The magazine lever is CNC machined from 17-4 stainless steel then glass bead blasted

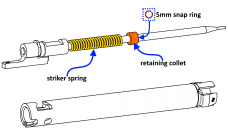

- The coil spring for the magazine release lever is made from piano wire and then zinc plated

Fitting Guide

(1) Assembly is required. The kit requires your factory bottom metal to be disassembled first. If in doubt, we can provide advice via email but a competent gunsmith may be required to undertake the installation. Minimum tools required for assembly are:

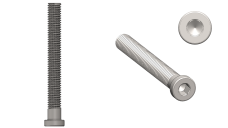

- 3mm metric hex key

- 4mm metric hex key

- small nylon punch

- 2mm (or 1.5mm) steel pin punch

- flat smooth file

- small wire cutters

- nylon bench block

- gunsmith's hammer

(2) The magazine release lever is deliberately manufactured to the maximum possible length where, with the supplied pillars installed, AICS magazines just click in and the bolt just clears the feedlips. Many shooters will want a slightly looser fit than this, whereas some will not. We have tested this precise fit with multiple magazines from Accuracy International, Accurate Mag, Alpha Industries, Magpul, and MDT. For a reliable fit to your specific rifle the magazine lever may need to be filed down to suit your personal preferences. We recommend first assembling and testing the DBM to your rifle. If the lever is shortened, we recommend only taking 0.5mm off the tip before refitting and testing magazine function.

(3) For the coil spring that provides tension to the magazine release lever, you can either reuse the one from your factory bottom metal or the one we provide. Ours is deliberately manufactured slightly longer than required and cannot be installed at full length. We supply 3 coil springs, only 1 coil spring is required. Use wire cutters to remove coils until you have achieved the tension preferred - which in most cases will be by removing between 3 to 5 coils. If you cut off too many and aren't satisfied with the tension, you have 2 spare springs remaining. Test magazine release thoroughly based on your shooting style, with this design some shooters will remove magazines using their index finger (generally requires less tension) whilst others with their thumb (generally requires more tension).

(4) Take care when assembling the magazine release lever, spring and dowel pin. Close attention is needed to avoid marring the anodized surface of the triggerguard when tapping in the dowel pin to secure the magazine release lever and the spring. Use a nylon punch to first get dowel pin in 95% of the way, then carefully use a 1.5mm or 2mm brass or steel pin punch to finish placing it with one firm tap. We recommend placing the triggerguard against a padded surface or on nylon bench block to drive in the dowel pin. Note that the dowel pin is splined on one side and is designed to sit slightly recessed from either face of the triggerguard.