Tikka T3 / T3x - DBM for factory magazines

- Brand: Lumley Arms

- Product Code: T3-DBM-FACTORY

- Fitting Guide (for OEM synthetic stocks)

- Bedding Guide (customer written)

- Availability: In Stock

-

$99.00

Available Options

Our stock: in stock

Or buy from a distributor:

Tikka T3 / T3x

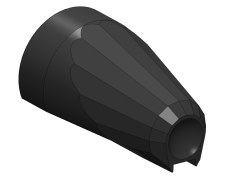

DBM for factory magazines - Titanium and 7075-T76 alloy

Read the full review of this DBM fitted to a custom ultralight T3 build from the April 2021 edition of Australian Shooter (reprinted by permission of the Sporting Shooters’ Association of Australia)

Notes

- This DBM will fit the OEM walnut and laminate stocks without modification. It is not a guaranteed 'drop-in' fit for the OEM synthetic stocks due to the very poor tolerances involved with the molding process used to manufacture these stocks. It will generally press in by hand however some force may be required and in some cases the DBM will need to be tapped in using a nylon block and nylon-tipped hammer. More details in the fitting guide section below.

- There are two anodized color options (black or silver), however we only do one production run of silver each year due to lower demand so this color can often be unavailable.

Features

- Very light - weighs under 3oz (83.5g)

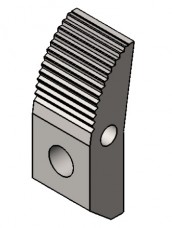

- The body of DBM is machined from high grade 7075-T76 aluminum alloy

- The trigger guard is machined from aerospace Ti6Al4V titanium alloy

- The magazine release lever is machined from aerospace Ti6Al4V titanium alloy

- All other components are stainless steel (either 304 or 316 grades)

- Accepts all T3 / T3x magazines, not compatible with the CTR magazine.

- Available in two colors, with slight variations between Al and Ti components

- Silver/grey color - garnet blasted finish to Ti parts, silver anodized body

- Black color - PVD finished Ti parts, Milspec type 3 hard coat anodized body

- The trigger guard is fully replaceable and serviceable

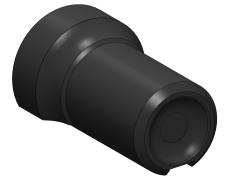

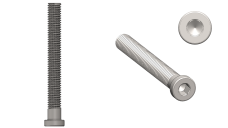

- Includes bedding pillars and non-tapered hex head screws (both 316 stainless)

- Arctic triggerguard design also available, see here

Fitting Guide

Both a fitting guide and bedding guide are available to download in PDF format (with step-by-step photos) at the top of this page in the section above the price.- Our DBM is 100% identical to the factory inlet, we measured a number of OEM synthetic DBMs to determine the correct inlet profile. Don't rely on your particular unit being correct, particularly if you have an OEM synthetic stocked rifle.

- Our DBM does not require any modification to the stock aside from drilling the action screw holes out to 10mm to fit the pillars (if applicable).

- In almost all cases our DBM be a 'drop in' fit for OEM timber or laminate stocks.

- The OEM synthetic stocks have very poor tolerances due to shrinkage after molding. When fitted to these stocks, the DBM in most cases will need to be gently tapped into the inlet.

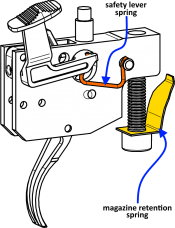

- Our magazine release lever is designed to lock the magazines up tight. The plastic original is typically shorter by up to 0.5mm to 0.75mm than it needs to be (varies based on degree of wear / distortion from use). This sloppy tolerance is partly why the tension spring is there to take up the slack. Due to differences between individual magazines, the top of our lever may need to be shortened between 0.5mm to 0.75mm for your particular rifle and magazine(s). This is quickly and easily done by just 4 or 5 firm swipes with a metal file (with lever removed from DBM and secured in a vise).

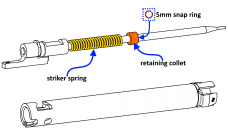

- Our DBM is very rigid - whereas the plastic original is not. For this reason the factory tension spring is rigid (0.50mm thick) and excessively angled pushing the magazine forwards to counter the flex of the factory plastic parts. This causes problems for some customers with the magazine not clipping into our DBM unless it is pulled backwards against this tension spring when inserted. To correct this spring tension, remove it from the trigger housing (5mm hex key required) and reduce the angle closest to the screw hole to 90 degrees by bending it whilst clamped in a vise.

- Don't rely on your stock having the correct spacing between the action and DBM at either the front or rear action screws - use our pillars or measure the tangs (front: 21.7mm / 0.854" and rear: 33mm / 1.3"). Test fit the DBM to the action first using only the pillars and action screws (no stock) to check magazine function.

- It doesn't take long to fit this DBM and have it functioning reliably. Contact us us first if you are having difficulty - we do not recommend making any modifications to your stock, magazines or DBM!